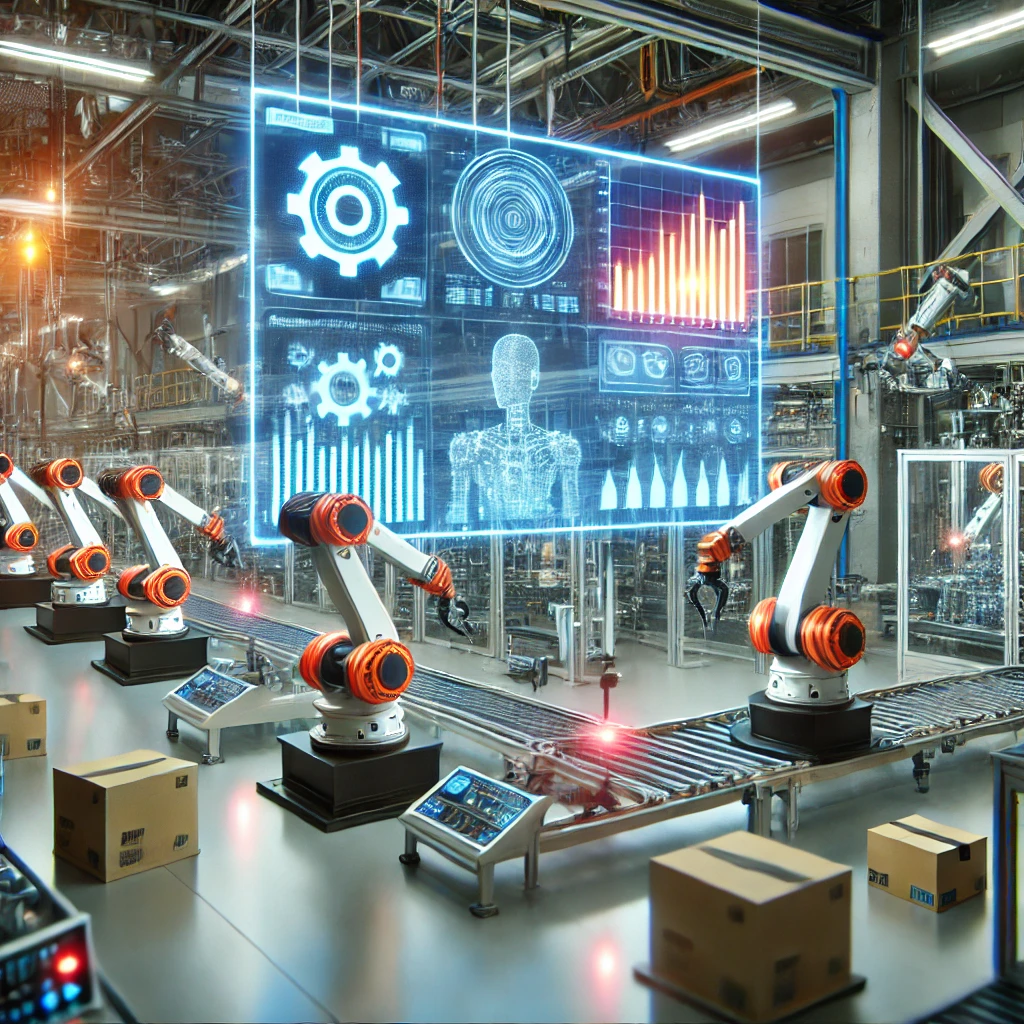

The rise of AI in manufacturing is dramatically reshaping how production lines operate. From automating routine tasks to ensuring that quality control processes are more accurate, AI has a massive impact on efficiency, reducing human error, and maintaining consistent output.

1. How AI Is Transforming Production Automation

AI-driven automation is no longer futuristic; it’s happening now. Manufacturers are leveraging artificial intelligence to automate repetitive and labor-intensive tasks. This allows companies to maximize throughput while minimizing labor costs and reducing errors. AI systems analyze vast amounts of production data, helping predict equipment failures, optimize production schedules, and streamline workflows.

One of the most significant benefits of using AI in production is predictive maintenance. Sensors embedded in machinery feed real-time data to AI algorithms, which detect signs of wear or impending failure. This proactive approach minimizes downtime, improving the overall efficiency of manufacturing operations.

2. Quality Control with AI: Precision at Every Step

In modern manufacturing, quality control is critical. AI-based inspection systems outperform traditional quality checks by using machine learning to detect defects that may go unnoticed by the human eye. These systems can analyze products in real-time, ensuring that any deviations are flagged immediately, which reduces waste and ensures customer satisfaction.

For example, computer vision technologies powered by AI are employed in production lines to assess product quality. These systems continuously improve their accuracy through machine learning, identifying imperfections in shape, size, and color, guaranteeing products meet strict standards before they leave the factory.

3. Benefits of AI in Manufacturing

- Increased Efficiency: Automating production processes leads to faster throughput and reduces operational costs.

- Improved Accuracy: AI minimizes errors in both production and quality control, ensuring products are consistently high-quality.

- Predictive Maintenance: AI-powered tools anticipate machine failures, preventing costly repairs and downtime.

- Data-Driven Decisions: Manufacturers use AI to make better decisions by analyzing real-time and historical data, optimizing processes and supply chains.

4. Real-World Applications of AI in Manufacturing

Several industries have already embraced AI. In automotive manufacturing, AI-powered robots are assembling vehicles faster and with greater precision. In electronics, AI ensures that complex circuits are tested for faults. Pharmaceutical companies use AI to monitor production lines for contamination or irregularities, ensuring the highest quality standards for medicines.

The Future of Manufacturing with AI

As AI continues to advance, its role in manufacturing will only grow. From automating production processes to enhancing quality control systems, AI offers unparalleled opportunities for businesses looking to stay competitive in today’s market.

Visit our other website: machinepwr.com